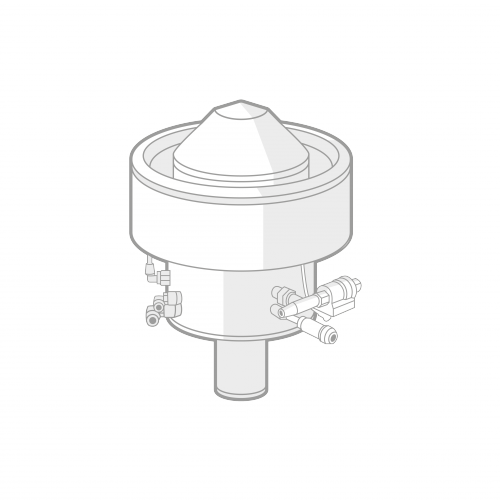

SoliValve®250 technology

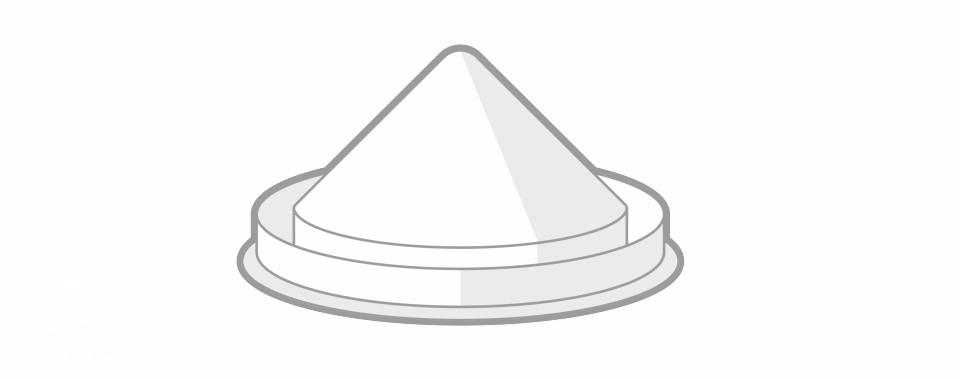

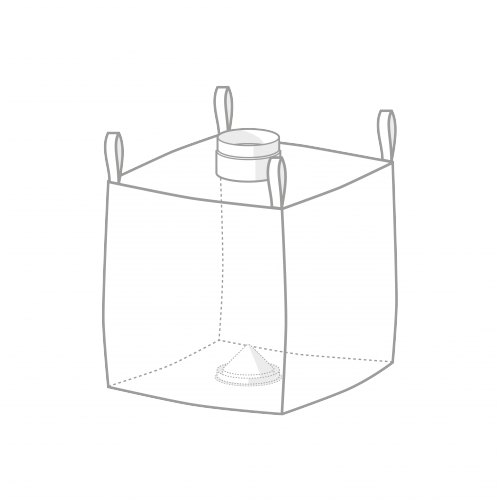

The SoliValve®250 allows for the first time fully automatic and contained handling of FIBC (BigBags), IBCs (rigid containers), drums etc. thanks to its universal Passive-SoliValve®. These are compatible with the Active docking units suitable for filling and discharging powders like APIs, Food Additives, Enzymes, Pigments etc. within all major process industries.

SoliValve®250 is also a very accurate metering device, avoiding the use of additional devices such as rotary valves or dosing screws to meter your products. Moreover, the SoliValve®250 doses the material vertically from the storage container, allowing re-closing of partially empty vessel and changing to a next ingredient without the need to empty the dosing hopper.

SoliValve®250 systems are installed in over 24 countries all over the world since 2005.

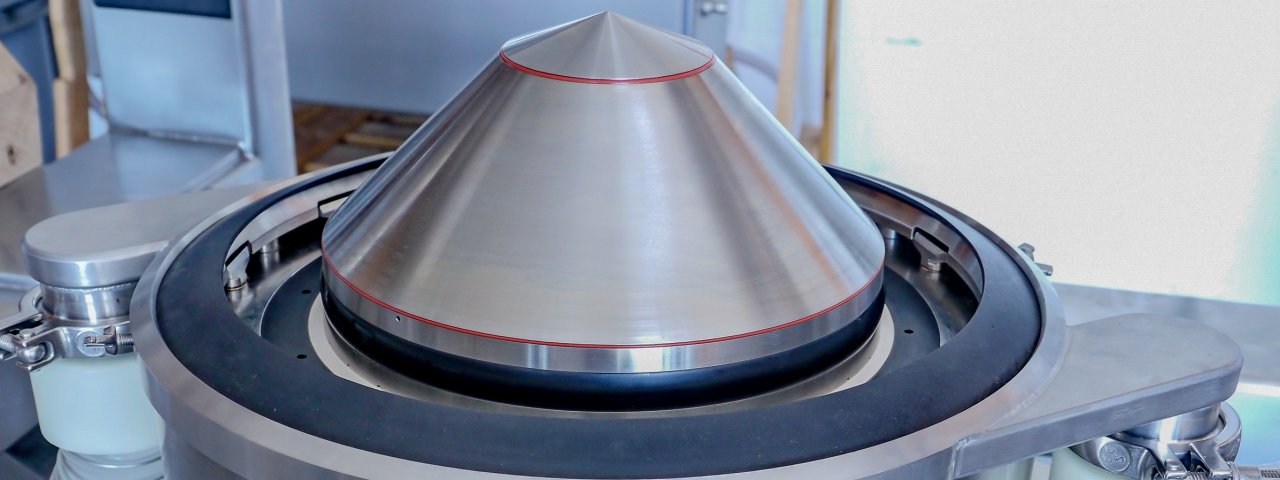

Test trials with your powder welcomed!

Visval offers to customers from all over the world a fully comprehensive test lab to conduct discharge & dosing tests. Upon request, we can deliver the SoliValve® to your site in order to conduct the tests. We believe that there is no better way to convince a customer than when he can see the system working from his own eyes.

Contact us for a test trial with your powder!