Cost effective

Summary of the saving advantages of the SoliVale®

- No proprietary Rigid IBC solution => the customer can freely choose his suppliers

- Cheap plastic injected FIBC alternative to Rigid IBC, even for standard BigBags with spout

- No particular operating height required

- De-dusting system not required thanks to the high level of containment of the SoliValve® system

- Reduction of dust explosion class thanks to dust free powder transfer of the SoliValve® system

- Additional dosing system not needed, SoliValve® is already equipped for precise dosing

- Completely automatic => less operator work, saving on running costs

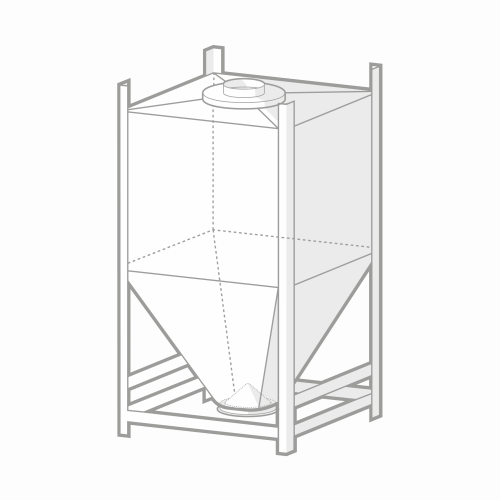

Cost effective solution for Rigid IBC

Compared to the other Cone Valve systems with their expensive proprietary Rigid IBCs, the SoliValve® offers a significant benefit for customers using large number of Rigid IBCs (known as bins or containers as well).

The customer is free to produce his IBCs himself or to order them from the supplier of his choice. Local manufacturing, for example for the Asian market, will bring several benefits above and beyond cost only: reduced lead time, reduce environmental impact, use of local workforce, etc.

The Passive-SoliValve® is then attached to the Rigid IBC using a standardized Trip-Clamp ferrule or customized flange and can be easily and rapidly dismounted for cleaning.

The Passive cone is made of injected plastic, therefore easy and cheap to replaced when worn out in comparison with other solution that requires time consuming operations to replace expensive seals.

learn more about the Passive-SoliValve® for Rigid IBC.

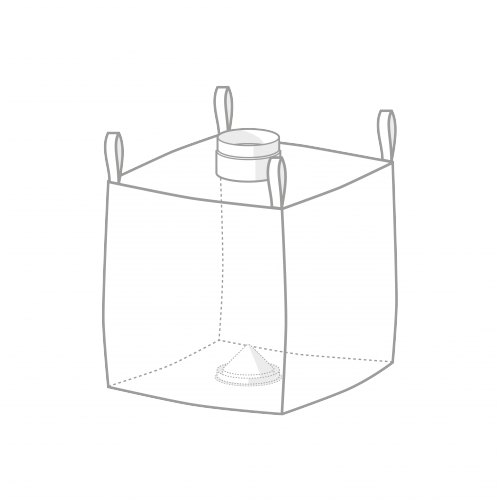

Cost effective solution for FIBC (BigBag)

The SoliValve® system allows as well the usage of cheap one way FIBC (or BigBags) instead of expensive IBC containers.The SoliBag® (FIBC with Passive-SoliValve®) is a very cost-effective alternative to the IBC containers.

The crimped version of the Passive-SoliValve® is made of injected plastic, therefore it is cost effective and suitable for a one-way or multi-way use.

The advantage of the one way FIBC is that is doesn't need to be cleaned and disinfected afterward like an IBC. It is simply disposed.

There is even a reusable Passive-SoliValve® version for the standard FIBC with spout. It can be fitted to an already filled BigBag to allow automatic and dust-free discharging. After emptying the BigBag, it can be reused again and again, making possible to benefit from the SoliValve® technology with a minimum of investments.

learn more about the Passive-SoliValve® for FIBC.

Infrastructure investment savings

The SoliValve® system not only allows the end user to save on the FIB/IBC, but as well on the investment for a new installation:

-The automatic docking requires no particular operating height due to ergonomic factors. Docking is possible at floor level.

-A de-dusting system can be dispensed with because of the high level of containment of the SoliValve® system.

-Reduction of the dust explosion class is possible, therefore reducing the investment for additional expensive ATEX approved equipment. Learn more about safety and the usage of SoliValve in dust explosion zones here.

- The SoliValve® is capable of accurate and repeatable dosing saving you the costs of a additional dosing system.

Labour and running costs savings

The SoliValve® 250 system is completely automatic from the docking to the undocking of the IBC/FIBC. It required much less operator work than other systems, therefore allowing you to save on running costs (OPEX) as well.

With the touch of a button on the control panel, the operator can automatically connect the container to the SoliValve® and start the discharging or filling. Same for the disconnection.